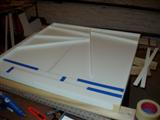

Changes & Progress ReversalOK, so I think I've completely decided on switching over to the new construction method. It will afford me many more benefits than my current construction. I will only be losing about 20 hours or so of work and about $100 worth in lumber that can't be used any more.

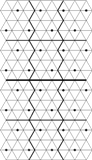

The new method is similar to what other people have been doing, and I don't know why I never thought of it before. The only major difference is that I need to intersect 3 pieces of wood, instead of their two (triangles, instead of squares).

For reference, see

this post and this image:

The big split between halves half-way down will still be there, but everything else will be changing. My plan is to have the pixel walls be about 2" tall (I could maybe go smaller too) and be about 1/2" thick plywood. I would use 1/4" plywood, but I need to have the outer walls be 1/2 the thickness of the inner walls. This way, I can abut any two wall sections seamlessly.

Every 5.5" (the pixel length), there will be one or two slits, depending on which axis the wood piece is, that extend a full 2/3 of the height of the wood, leaving only 1/3 (~0.66") of the wood remaining for structural integrity. The three axes of wood lengths will then be slotted and glued together (I shouldn't need anything more than glue for them; they're strong even without glue). This will give me a pseudo-honeycomb (except triangles instead of hexagons).

Then I can just affix a piece of plywood to the bottom (the thinner, the better) and I basically have the entire enclosure (minus the acrylic top, of course). On the outer walls, I was planning on using 1/4"-thick plywood, like I said, but it would be 3" tall, instead of 2". This would give me a subfloor with which I can mount the electronics and run the wiring. Since I won't be having any border around the wall, I need everything completely self-contained.

Well, almost completely. There's still the issue of the power supply. It's a full 2"x3.75"x5.8". Which means that I could mount it in an enclosure that hangs down an extra ~4" on the bottom of the bottom wall "module".

I should be able to have all of the connectors between the bottom and top modules (USB, power, SPI, and switches), as well as connectors for modules to the left and right of each of them, flush with the edge of the wall. The 1" margin on the bottom will be enough for this.

UpdatesI spent a whopping $18 on 70 feet of heat shrink tubing and 100' of 2-conductor 26ga. wire at Ax-Man today. I figured I should spend as little as possible for just testing. I got maily 1/8" tubing, with some 3/16" as well. The 1/8" is a little too big for what I need and it was as small as they had, so if I were to get more, I would get 1/16" or 3/32", depending on what suppliers had available. The wire worked decently and I finally figured out a way to solder the wires to the resistors and LEDs. The only problem is that it took a moderate amount of time, so I have a long way to go. I now have one LED triplet done (yay 0.4% completed!) and I've verified that it works. It's just over 19" long, so it should be long enough to go from the board to the furthest-away pixel. That's one nice thing about having separate driver boards; I can have the boards centered around the pixels they're powering and not have to deal with LED wiring that're several feet long.

Tomorrow, I must go buy lots of wood and start cutting. I will have to come up with a way to make 4'-long cuts in plywood with a jigsaw go fast and straight. I have 54 2"-tall pieces to cut and 36 3"-tall pieces to cut. Fun, fun!

Labels: Construction, Supplies